4.5.2 MIT-3 scenario

In MIT-3, as of 2020, the conversion is assumed to start in all sub-sectors to replace high- GWP refrigerants with a variety of refrigerants, with the refrigerant blends assumed to have an average GWP of 300. Conversion has been assumed to take six years for Article 5 Parties, and the manufacturing capacity is modelled to convert in equal portions per year during the period 2020-2025 (six years). The following graphs are for the Article 5 MIT-3 scenario, split into in the various R/AC sub-sectors.

Figure 4-13: Article 5 MIT-3 scenario with the demand for the R/AC sub-sectors, including both new manufacturing and servicing

Figure 4-13 shows the steep decrease in the first six years as of 2020, after which the curve flattens due to continued servicing needs only. Since some high-GWP equipment will have been manufactured until 2025, and has an average 12 year lifetime, supplies of high-GWP refrigerants will be continue to be required –in decreasing amounts– until about 2035-37. During 2010-2015, stationary AC and commercial refrigeration demands increase rapidly. With controls assumed on new manufacturing as of 2020, the high-GWP refrigerant demand in these sector decreases, being replaced by low-GWP refrigerants, which will account for 80% of total demand between after 2025-2030. This is a large improvement in climate impact, although with this GWP of 300, the large refrigerant volumes considered still have a certain climate impact, the relative importance of these refrigerants is now much lower in the GWP weighted graph. The demand increases again (even with a large percentage low GWP refrigerants) after 2032, due to assumed economic growth.

In Figure 4-14, the new manufacturing demand for the R/AC sub-sectors for high-GWP chemicals is given. By 2026, the demand for high-GWP refrigerants in new equipment manufacture falls to <20% of the 2019 peak value, then starts to increase again due to economic growth.

Figure 4-14: Article 5 MIT-3 scenario for new manufacturing demand for high-GWP refrigerants in the various R/AC sub-sectors in ktonnes CO2-eq. (compare Fig. 4-5 for non- Article 5 manufacturing demand)

Figure 4-15: Article 5 MIT-3 scenario with the servicing demand for the various subsectors in ktonnes CO2-eq. (compare Fig. 4-6 for non-Article 5 servicing demand)

Figure 4-15 shows the amounts of high-GWP refrigerants in ktonnes CO2-eq. that will be needed for servicing the installed equipment. This varies between sectors and according to the speed of the manufacturing transition (the slower the manufacturing transition, the longer the servicing tail). Amounts (expressed in GWP weighted terms) will increase again after 2030- 2032.

4.5.3 Impact of manufacturing conversion periods in the MIT-3 scenario

Figure 4-16 shows the demand dependent on the rate of conversion or the length of the conversion period, which is an important parameter (unchanged from what was given in (UNEP, 2015)). The six years conversion period in manufacturing for all sub-sectors results in a decrease of approximately 40% by the year 2026, and about 50% by 2030. After 2026, the remaining demand is for servicing, and only declines by about 10% over the following four years (2026-2030). At the other extreme, a twelve years manufacturing conversion period only leads to a negligible reduction by 2026, and a 25% reduction by 2030. There is a difference of about 350 Mt CO2-eq. between the 6 and 12 year manufacturing conversion periods after 2025.

Figure 4-16: Article 5 MIT-3 demand scenario for all R/AC sectors for new manufacturing conversion periods of 6-8-10-12 years in Mt CO2-eq. (UNEP, 2015)

A twelve year conversion period does not yield a lower demand until after 4-5 years after the start of the conversion in the year 2020. The build-up of the servicing demand (from the manufacturing that has not yet been converted) causes this increasing profile in the demand curve (2020-2025). Ten years after the start of the conversion in 2020, a demand reduction of 20-25% can be observed in this case. In the year 2026, the demand for the 12 years conversion period is almost twice as high as for the six years conversion period, which underscores that a rapid conversion will be very important. It will be clear that there is a direct relationship of the shape of the curves to the conversion period. There are also cost implications. A six year conversion period would imply twice the costs in the first six years after 2020 (2021-2026), compared to the 12 years conversion period, where the same amount will be spread over 12 years (see further in chapter 6).

4.5.4 MIT-4 scenario

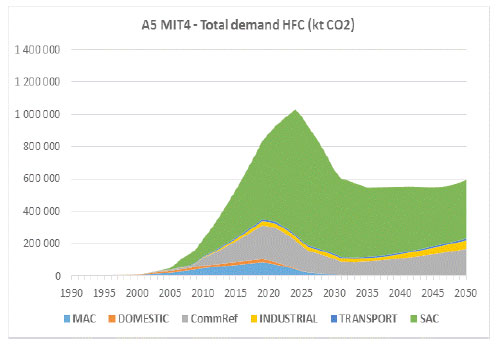

Figure 4-17: Article 5 MIT-4 total demand scenario by R/AC sub-sectors in ktonnes CO2- eq. (compare Figure 4-13 for MIT-3)

Figure 4-17 includes both manufacturing and servicing, and is the same as Fig 4-13 for MIT- 3, except for the stationary AC sub-sector graph (in green), which continues to increase until 2025, before declining. MIT-4 parameters are otherwise identical to MIT-3 (replacement refrigerant blends GWP 300; 6 year manufacturing conversion).

Figure 4-18 also shows the data for HFCs used in new manufacturing only. The various subsectors now decline to zero new manufacturing demand at different times.

Demand in GWP weighted terms increases again after 2030-2032.

Figure 4-18: Article 5 MIT-4 scenario for new manufacturing demand for the various R/AC sub-sectors in ktonnes CO2-eq. (compare Fig. 4-14 for MIT-3)

Figure 4-19: Article 5 MIT-4 scenario with the servicing demand for the various subsectors in ktonnes CO2-eq. (stationary AC starting in 2025, and assuming a conversion of manufacturing over a period of six years) (compare Fig. 4-15 for MIT-3)

In 2020-2025, demand for new manufacturing peaks at about 550 Mt CO2-eq, and demand for servicing is about 300 Mt CO2-eq, but by 2026, these values are reversed. Servicing demand peaks around 2027, at a high level of about 560 Mt CO2-eq., due to the late conversion of the stationary AC sector (assumed to rely on the refrigerants R-410A and R-407C).The above graphs give a good impression of the impact of the stationary AC sector.

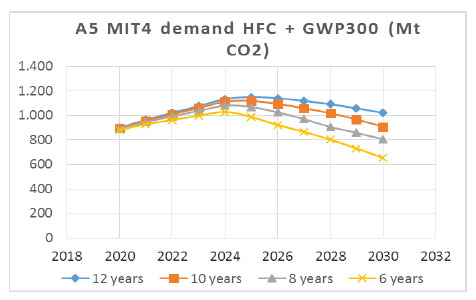

4.5.5 Impact of manufacturing conversion periods in the MIT-4 scenario

Figure 4-20: Article 5 MIT-4 demand scenario for all R/AC sectors combined for new manufacturing conversion periods of 6-8-10-12 years in Mt CO2-eq. (compare Figure 5-16 for the MIT-3 scenario) (UNEP, 2015)

Impact of the rate of manufacturing conversion: a long period of manufacturing conversion will result in an enhanced and long-lasting demand for high-GWP HFCs for servicing.

Fig. 4-20 gives the four curves for the six, eight, ten and 12 years manufacturing conversion periods for all refrigeration and AC sub-sectors together (as in (UNEP, 2015)). The delayed manufacturing conversion for stationary AC from 2020 to 2025 makes a large difference in the high-GWP demand.

For a six year conversion period, the HFC demand for MIT-3 and MIT-4 is projected for 2030 as (compare Figs. 4-16 and 4-20):

• MIT-3 (stationary AC conversion starting at 2020) – 410 Mt CO2-eq

• MIT-4 (stationary AC conversion starting at 2025) – 640 Mt CO2-eq

The delay of five years for stationary AC conversion to 2025 results in a more than 50% increase in annual HFC climate impact by the year 2030.

The MIT-4 scenario has a major adverse climate impact compared to MIT-3. There are cost implications of the MIT-4 scenario.

A delay of five years for starting SAC conversion, and a six year manufacturing conversion period, means that the overall costs have to be considered over a longer period than six years (i.e., over 12 years (rather than six years)).

4.5.6 MIT-5 scenario

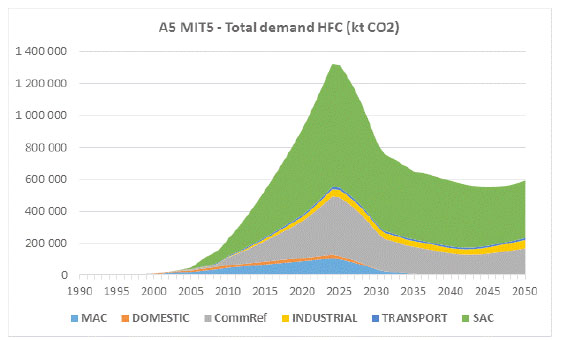

Figure 4-21: Article 5 MIT-5 scenario by R/AC sub-sectors in ktonnes CO2-eq. (compare Figure 4-13 and 4-17 for MIT-3 and MIT-4)

Figure 4-21 includes both manufacturing and servicing, and is similar to Figs 4-13 and 4-17 for MIT-3 and MIT-4 (replacement refrigerant blends at a GWP of 300; six year manufacturing conversion).

Figure 4-22 also shows the same data just for HFCs used in new manufacturing. All subsectors decline to zero new manufacturing demand at the same time (as in MIT-3).

Figure 4-22: Article 5 MIT-5 scenario for new manufacturing demand for the various R/AC sub-sectors in ktonnes CO2-eq. (manufacturing conversion over a period of six years) (compare Figure 4-14 and 4-19 for MIT-3 and MIT-4)

Figure 4-23: Article 5 MIT-5 scenario with the servicing demand for the various subsectors in ktonnes CO2-eq. (assuming a conversion of manufacturing over a period of six years) (compare Figure 4-15 and 4-19 for MIT-3 and MIT-4)

In 2025, demand for new manufacturing peaks at about 760 Mt CO2-eq, and demand for servicing is about 650 Mt CO2-eq. After 2030, the manufacturing demand has gone down to a little more than 100 Mt CO2-eq., then increases again due to assumed economic growth to more than 200 Mt CO2-eq.

Servicing demand peaks at about 660 Mt CO2-eq., due to the late conversions of all subsectors, then decreases until around 2045 to about 330 Mt CO2-eq., after which year it starts to increase again (economic growth assumed).

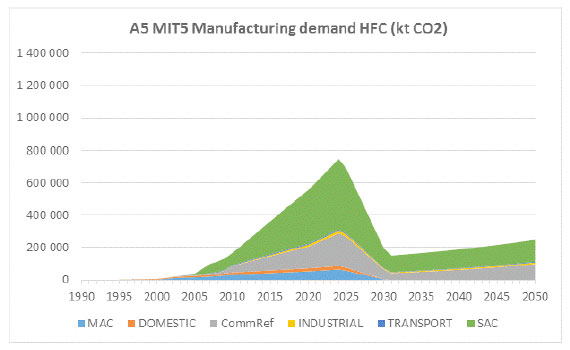

4.5.7 Impact of manufacturing conversion periods in the MIT-5 scenario

Figure 4-24: Article 5 MIT-5 demand scenario for all R/AC sectors combined for new manufacturing conversion periods of 6-8-10-12 years (compare Figures 4-16 and 4-21 for the MIT-3 and MIT-4 scenarios) (UNEP, 2015)

The impact of the rate of manufacturing conversion is that a long period of manufacturing conversion will result in an enhanced and long-lasting demand for high-GWP HFCs for servicing.

Fig. 4-24 gives the 4 curves for the six, eight, ten and 12 years manufacturing conversion periods for all refrigeration and AC sub-sectors together (again unchanged from what was given in (UNEP, 2015)). The delayed manufacturing conversion for all sub-sectors as of 2025 makes a large difference. While demand for a six year conversion period decreases substantially between 2025 and 2030, a 12 year conversion period only results in a small decrease between 2025 and 2030 (about 100 Mt CO2-eq.).

For a six year conversion period HFC demand is projected for 2030 for MIT-3 and MIT-5 as:

- MIT-3 (all conversions starting at 2020) – 410 Mt CO2-eq.

- MIT-5 (all conversions starting at 2025) – 810 Mt CO2-eq.

The delay of five years for all sub-sector conversions to 2025 results in roughly a 100% increase in annual weighted climate impact by the year 2030.

The MIT-5 scenario has a major adverse climate impact compared to MIT-3 (and also to some degree to MIT-4). Furthermore, cost implications of the MIT-5 scenario will therefore be larger than for MIT-3 and MIT-4. In the case of a six year manufacturing conversion period, overall costs will have to be covered over six years (expansion to 12 years does not seem desirable given the climate impact numbers).

4.6 Refrigerant demand and mitigation benefit numbers

On the basis of the development of the demand for the various refrigerants and their replacements for the various sub-sectors (high-GWP and low-GWP alternatives), total demand in tonnes, as well as in GWP based CO2-eq. tonnes can be calculated. The tables below extend to 2050 the non-Article 5 and Article 5 demand in tonnes and Mt-CO2 eq. for BAU, MIT-3 and MIT-5 scenarios.

Table 4-3: Current and future refrigerant demand for (refrigerant) ODS alternatives (BAU scenario) for the period 2010-2050 in non-Article 5 Parties (tonnes)

| 2010 | 2015 | 2020 | 2025 | 2030 | ||

| nA5 BAU | HFC-‐134a | 79,097 | 77,977 | 72,872 | 76,869 | 82,356 |

| R-‐404A + R-‐507 | 17,084 | 18,376 | 18,584 | 19,357 | 22,780 | |

| R-‐407C | 11,195 | 26,802 | 34,942 | 43,946 | 50,402 | |

| R-‐410A | 39,385 | 77,354 | 94,230 | 114,001 | 131,319 | |

| Low GWP | 7,011 | 11,844 | 13,907 | 16,802 | 20,538 | |

| Total | 153,772 | 212,353 | 234,535 | 270,975 | 307,395 | |

| 2030 | 2035 | 2040 | 2045 | 2050 | ||

| nA5 BAU | HFC-‐134a | 82,356 | 93,316 | 108,107 | 125,265 | 145,166 |

| R-‐404A + R-‐507 | 22,780 | 26,151 | 30,221 | 34,960 | 40,470 | |

| R-‐407C | 50,402 | 58,256 | 67,534 | 78,291 | 90,760 | |

| R-‐410A | 131,319 | 151,966 | 176,170 | 204,229 | 236,758 | |

| Low GWP | 131,319 | 21,170 | 25,071 | 29,334 | 34,188 | |

| Total | 307,395 | 350,859 | 25,071 | 472,079 | 547,342 |

Table 4-4: Current and future refrigerant demand for (refrigerant) ODS alternatives (BAU scenario) for the period 2010-2050 in non-Article 5 Parties (ktonnes CO2-eq.)

| 2010 | 2015 | 2020 | 2025 | 2030 | ||

| nA5 BAU | HFC-‐134a | 102,825 | 101,370 | 94,733 | 99,930 | 107,064 |

| R-‐404A + R-‐507 | 67,397 | 72,490 | 73,312 | 76,367 | 89,875 | |

| R-‐407C | 18,135 | 43,419 | 56,606 | 71,193 | 81,652 | |

| R-‐410A | 75,619 | 148,520 | 180,922 | 218,882 | 252,133 | |

| Low GWP | 8 | 10 | 13 | 19 | 27 | |

| Total | 263,984 | 365,809 | 405,586 | 466,391 | 530,751 | |

| nA5 BAU | HFC-‐134a | 107,064 | 121,311 | 140,539 | 162,845 | 188,716 |

| R-‐404A + R-‐507 | 89,875 | 103,180 | 119,238 | 137,936 | 159,679 | |

| R-‐407C | 81,652 | 94,374 | 109,405 | 126,831 | 147,032 | |

| R-‐410A | 252,133 | 291,774 | 338,246 | 392,120 | 454,575 | |

| Low GWP | 27 | 32 | 38 | 44 | 51 | |

| Total | 530,751 | 610,671 | 707,466 | 819,776 | 950,053 |

Table 4-5: Current and future refrigerant demand for (refrigerant) ODS alternatives (MIT- 3 scenario) for the period 2010-2050 in non-Article 5 Parties (tonnes)

| MIT-‐3 | 2010 | 2015 | 2020 | 2025 | 2030 | |

| nA5 3-‐year conversion 2020 | HFC-‐134a | 79,097 | 77,977 | 18,758 | 13,415 | 7,154 |

| R-‐404A + R-‐507 | 17,084 | 18,376 | 12,882 | 5,531 | 2,046 | |

| R-‐407C | 11,195 | 26,802 | 13,987 | 10,417 | 2,716 | |

| R-‐410A | 39,385 | 77,354 | 22,337 | 15,831 | 4,127 | |

| Low GWP | 7,011 | 11,844 | 133,007 | 189,570 | 252,410 | |

| Total | 153,772 | 212,353 | 200,971 | 234,764 | 268,453 | |

| 2030 | 2035 | 2040 | 2045 | 2050 | ||

| nA5 3-‐year conversion 2020 | HFC-‐134a | 14,013 | 3,941 | 4,497 | 5,153 | 5,923 |

| R-‐404A + R-‐507 | 2,046 | 155 | 121 | 94 | 73 | |

| R-‐407C | 2,716 | 0 | 0 | 0 | 0 | |

| R-‐410A | 4,127 | 0 | 0 | 0 | 0 | |

| Low GWP | 252,410 | 353,069 | 409,796 | 475,307 | 551,172 | |

| Total | 268,453 | 357,165 | 414,414 | 480,554 | 557,168 |

Table 4-6: Current and future refrigerant demand for (refrigerant) ODS alternatives (MIT- 3 scenario) for the period 2010-2050 in non-Article 5 Parties (ktonnes CO2-eq.)

| MIT-‐3 | 2010 | 2015 | 2020 | 2025 | 2030 | |

| nA5 3-‐year conversion 2020 | HFC-‐134a | 102,825 | 101,370 | 24,384 | 17,441 | 9,301 |

| R-‐404A + R-‐507 | 67,397 | 72,490 | 50,811 | 21,816 | 8,072 | |

| R-‐407C | 18,135 | 43,419 | 22,660 | 16,876 | 4,401 | |

| R-‐410A | 75,619 | 148,520 | 42,886 | 30,396 | 7,923 | |

| Low GWP | 8 | 10 | 29,826 | 43,478 | 58,396 | |

| Total | 263,984 | 365,809 | 170,568 | 130,007 | 88,093 | |

| 2030 | 2035 | 2040 | 2045 | 2050 | ||

| nA5 3-‐year conversion 2020 | HFC-‐134a | 9,301 | 5,124 | 5,846 | 6,699 | 7,700 |

| R-‐404A + R-‐507 | 8,072 | 611 | 475 | 370 | 288 | |

| R-‐407C | 4,401 | 0 | 0 | 0 | 0 | |

| R-‐410A | 7,923 | 0 | 0 | 0 | 0 | |

| Low GWP | 58,396 | 72,898 | 84,498 | 97,948 | 113,542 | |

| Total | 88,093 | 78,633 | 90,819 | 105,017 | 121,530 |

The following can be observed for non-Article 5 Parties and the MIT-3 scenario, which results in the conversion of manufacturing by the year 2020:

• The demand for various HFCs in non-Article 5 Parties is assumed to decrease substantially between 2015 and 2030, by more than 70% in climate weighted terms, thereafter the decrease will be much slower (values are already very low);

• The demand for the stationary AC sub-sector decreases enormously between 2025 and 2030, because virtually all requirements for high-GWP refrigerants disappear. The amount of low-GWP refrigerants in climate terms now becomes very relevant (due to the remaining GWP of 300 assumed for low-GWP refrigerant blends).

A number of tables containing the demand data in tonnes and ktonnes CO2-eq. extended to 2050 for the BAU, MIT-3 and MIT-5 scenarios in Article 5 Parties are given below.

| 2010 | 2015 | 2020 | 2025 | 2030 | ||

| A5 BAU | HFC-‐134a | 54,393 | 74,524 | 100,162 | 127,267 | 161,107 |

| R-‐404A + R-‐507 | 13,085 | 36,404 | 63,963 | 111,927 | 167,690 | |

| R-‐407C | 16,543 | 55,278 | 101,216 | 174,433 | 285,500 | |

| R-‐410A | 40,975 | 106,661 | 192,770 | 284,682 | 364,845 | |

| Low GWP | 22,430 | 29,318 | 39,132 | 51,975 | 69,915 | |

| Total | 147,426 | 302,185 | 497,243 | 750,284 | 1,049,057 | |

| 2030 | 2035 | 2040 | 2045 | 2050 | ||

| A5 BAU | HFC-‐134a | 161,107 | 204,027 | 257,413 | 324,537 | 409,494 |

| R-‐404A + R-‐507 | 167,690 | 223,579 | 287,745 | 361,077 | 449,614 | |

| R-‐407C | 285,500 | 372,998 | 457,406 | 532,391 | 587,361 | |

| R-‐410A | 364,845 | 427,266 | 479,588 | 524,488 | 566,180 | |

| Low GWP | 69,915 | 85,957 | 104,807 | 127,577 | 155,209 | |

| Total | 1,049,057 | 1,313,827 | 1,586,959 | 1,870,070 | 2,167,858 |

Table 4-8: Current and future refrigerant demand for (refrigerant) ODS alternatives (BAU scenario) for the period 2010-2050 in Article 5 Parties (ktonnes CO2-eq.)

| 2010 | 2015 | 2020 | 2025 | 2030 | ||

| A5 BAU | HFC-‐134a | 70,712 | 96,880 | 130,210 | 165,447 | 209,440 |

| R-‐404A + R-‐507 | 51,584 | 143,511 | 252,168 | 441,229 | 661,025 | |

| R-‐407C | 26,799 | 89,550 | 163,971 | 282,581 | 462,511 | |

| R-‐410A | 78,671 | 204,789 | 370,118 | 546,589 | 700,502 | |

| Low GWP | 62 | 115 | 203 | 314 | 469 | |

| Total | 227,828 | 534,845 | 916,670 | 1,436,160 | 2,033,947 | |

| 2030 | 2035 | 2040 | 2045 | 2050 | ||

| A5 BAU | HFC-‐134a | 209,440 | 265,234 | 334,637 | 421,897 | 532,343 |

| R-‐404A + R-‐507 | 661,025 | 881,313 | 1,134,195 | 1,423,289 | 1,772,283 | |

| R-‐407C | 462,511 | 604,256 | 740,997 | 862,474 | 951,525 | |

| R-‐410A | 700,502 | 820,350 | 920,809 | 1,007,017 | 1,087,066 | |

| Low GWP | 478 | 601 | 752 | 940 | 1,171 | |

| Total | 2,033,956 | 2,571,754 | 3,131,390 | 3,715,617 | 4,344,388 |

- The demand for various high-GWP HFCs in Article 5 Parties is (still) calculated to increase by a factor 3-4 in the BAU scenario in climate terms during 2015-2030 and by a factor of 7-8 during 2015-2050;

- The BAU scenario shows a large growth in demand for the high-GWP refrigerants R-404A, R-407C and R-410A, mainly due to the external (economic growth) factors.

Table 4-9: Current and future refrigerant demand for (refrigerant) ODS alternatives (MIT- 3 scenario) for the period 2010-2050 in Article 5 Parties (tonnes)

| MIT-‐3 | 2010 | 2015 | 2020 | 2025 | 2030 | |

| A5 6-‐year conversion 2020 | HFC-‐134a | 54,393 | 74,649 | 91,265 | 48,357 | 39,331 |

| R-‐404A + R-‐507 | 13,085 | 36,679 | 58,259 | 36,123 | 12,751 | |

| R-‐407C | 16,543 | 55,278 | 92,804 | 58,029 | 20,684 | |

| R-‐410A | 40,975 | 106,661 | 170,273 | 65,015 | 18,972 | |

| Low GWP | 22,430 | 29,318 | 87,522 | 562,500 | 991,332 | |

| Total | 147,426 | 302,585 | 500,123 | 770,024 | 1,083,070 | |

| MIT-‐3 | 2030 | 2035 | 2040 | 2045 | 2050 | |

| A5 6-‐year conversion 2020 | HFC-‐134a | 39,331 | 39,386 | 47,809 | 57,936 | 70,499 |

| R-‐404A + R-‐507 | 12,751 | 2,970 | 1,576 | 3,306 | 5,077 | |

| R-‐407C | 20,684 | 13,059 | 4,411 | 0 | 0 | |

| R-‐410A | 18,972 | 13,467 | 4,267 | 0 | 0 | |

| Low GWP | 991,332 | 1,244,943 | 1,528,895 | 1,808,828 | 2,092,281 | |

| Total | 1,083,070 | 1,313,825 | 1,586,958 | 1,870,070 | 2,167,857 |

Table 4-10: Current and future refrigerant demand for (refrigerant) ODS alternatives (MIT-3 scenario) for the period 2010-2050 in Article 5 Parties (ktonnes CO2-eq.)

| MIT-‐3 | 2010 | 2015 | 2020 | 2025 | 2030 | |

| A5 6-‐year conversion 2020 | HFC-‐134a | 70,712 | 96,880 | 117,959 | 61,810 | 49,670 |

| R-‐404A + R-‐507 | 51,584 | 143,511 | 227,693 | 141,897 | 50,899 | |

| R-‐407C | 26,799 | 89,550 | 150,343 | 94,007 | 33,508 | |

| R-‐410A | 78,671 | 204,789 | 326,924 | 124,828 | 36,425 | |

| Low GWP | 62 | 115 | 11,394 | 123,925 | 230,156 | |

| Total | 227,828 | 534,858 | 834,313 | 546,467 | 400,658 | |

| MIT-‐3 | 2030 | 2035 | 2040 | 2045 | 2050 | |

| A5 6-‐year conversion 2020 | HFC-‐134a | 49,670 | 51,201 | 62,151 | 75,316 | 91,649 |

| R-‐404A + R-‐507 | 50,899 | 11,716 | 6,210 | 13,024 | 20,005 | |

| R-‐407C | 33,508 | 21,156 | 7,146 | 0 | 0 | |

| R-‐410A | 36,425 | 25,856 | 8,192 | 0 | 0 | |

| Low GWP | 230,156 | 299,573 | 365,941 | 426,394 | 481,920 | |

| Total | 400,658 | 409,502 | 449,640 | 514,734 | 593,574 |

The following can be observed for the Article 5 Parties, in the case of the MIT-3 scenario:

- The demand for various high-GWP HFCs in Article 5 Parties is estimated to increase by more than 50% between 2015 and 2020 in climate terms, however, it decreases again to the 2015 level in the year 2025;

- The most surprising result is that the demand in climate terms is reduced by only 20-25% in the year 2030, compared to 2015 (of course, it is much higher in the year 2020). This is due to the high growth assumed, in particular, for stationary AC, where, for all subsectors together, the use of replacement refrigerant blends with a GWP of 300 (at one million tonnes) is calculated to represent a climate impact of 230 Mt CO2-eq. in 2030;

- It should be realised that the proposed MIT-3 manufacturing conversion will be very demanding and the assumptions used here are based on the fact that institutional and industrial capacities can completely deal with the conversion in this timeframe.

Table 4-11: Current and future refrigerant demand for (refrigerant) ODS alternatives (MIT-5 scenario) for the period 2010-2050 in Article 5 Parties (tonnes)

| MIT-‐5 | 2010 | 2015 | 2020 | 2025 | 2030 | |

| A5 6-‐year conversion 2025 | HFC-‐134a | 54,393 | 74,524 | 100,162 | 115,545 | 60,851 |

| R-‐404A + R-‐507 | 13,085 | 36,404 | 63,963 | 101,843 | 54,014 | |

| R-‐407C | 16,543 | 55,278 | 101,216 | 160,942 | 108,166 | |

| R-‐410A | 40,975 | 106,661 | 192,770 | 254,067 | 104,162 | |

| Low GWP | 22,430 | 29,318 | 39,132 | 117,161 | 714,856 | |

| Total | 147,426 | 302,185 | 497,243 | 749,558 | 1,042,049 | |

| MIT-‐5 | 2030 | 2035 | 2040 | 2045 | 2050 | |

| A5 6-‐year conversion 2025 | HFC-‐134a | 60,851 | 44,532 | 48,104 | 58,047 | 70,499 |

| R-‐404A + R-‐507 | 54,014 | 29,994 | 11,445 | 3,515 | 5,077 | |

| R-‐407C | 108,166 | 30,160 | 21,180 | 7,194 | 0 | |

| R-‐410A | 104,162 | 83,830 | 55,193 | 16,085 | 0 | |

| Low GWP | 714,856 | 1,125,310 | 1,451,035 | 1,785,231 | 2,092,281 | |

| Total | 1,042,049 | 1,313,826 | 1,586,957 | 1,870,072 | 2,167,857 |

Table 4-12: Current and future refrigerant demand for (refrigerant) ODS alternatives (MIT-5 scenario) for the period 2010-2050 in Article 5 Parties (ktonnes CO2-eq.)

| 2010 | 2015 | 2020 | 2025 | 2030 | ||

| A5 6-‐year conversion 2025 | HFC-‐134a | 70,712 | 96,880 | 130,210 | 150,208 | 79,106 |

| R-‐404A + R-‐507 | 51,584 | 143,511 | 252,168 | 401,490 | 213,054 | |

| R-‐407C | 26,799 | 89,550 | 163,791 | 260,727 | 175,229 | |

| R-‐410A | 78,761 | 204,789 | 370,118 | 487,808 | 199,992 | |

| Low GWP | 62 | 115 | 203 | 16,637 | 166,480 | |

| Total | 227,828 | 534,845 | 916,670 | 1,316,870 | 833,861 | |

| 2030 | 2035 | 2040 | 2045 | 2050 | ||

| A5 6-‐year conversion 2025 | HFC-‐134a | 79,106 | 57,892 | 62,535 | 75,460 | 91,649 |

| R-‐404A + R-‐507 | 214,824 | 118,243 | 45,115 | 13,846 | 20,005 | |

| R-‐407C | 175,229 | 48,859 | 34,312 | 11,654 | 0 | |

| R-‐410A | 199,992 | 160,953 | 105,970 | 30,882 | 0 | |

| Low GWP | 166,332 | 265,216 | 342,666 | 419,344 | 481,920 | |

| Total | 835,483 | 651,163 | 590,598 | 551,186 | 593,574 |

In Tables 4-11 and 4-12 above, the following can be observed for the Article 5 Parties and the MIT-5 scenario:

• The MIT-5 scenario represents a much higher climate impact than the MIT-3 scenario. For the future, the question remains which scenario could or would be the most likely one that Article 5 Parties can and will follow;

• The demand for various high-GWP HFCs in Article 5 Parties is calculated to increase by a factor of 1.7 between 2015 and 2020 and by a factor 1.45 between 2020 and 2025, expressed in ktonnes CO2-eq.. (this corresponds more or less to the same growth in refrigerant demand in tonnes);

• One might conclude that the proposed MIT-5 manufacturing conversion is not expected to be too demanding and that institutional and industrial capacities should be able to deal with the conversion in this timeframe, if not before. This, of course, assumes the gradual

acceptance of alternatives for all sub-sectors before 2025, which seems to be definitely possible taking into account the pace of acceptance for many alternatives anticipated at present.

Table 4-13: Refrigerant demand for (refrigerant) ODS alternatives in the BAU, MIT-3, MIT-4 and MIT-5 scenarios for various periods in Article 5 Parties (n.b., in Mt CO2-eq.); the total concerns the total refrigerant demand over the period 2020-2050

| Period | 2020-‐2030 | 2031-‐2040 | 2041-‐2050 | Total |

| A5 BAU | 16016 | 26321 | 37874 | 80211 |

| A5 MIT-‐3 | 6349 | 4202 | 5257 | 15808 |

| A5 MIT-‐4 | 9762 | 5798 | 5540 | 21100 |

| A5 MIT-‐5 | 12069 | 6696 | 5719 | 24484 |

| Period | 2020-‐2030 | 2020-‐2040 | 2020-‐2050 |

| A5 BAU | 16016 | 42337 | 80211 |

| A5 MIT-‐3 | 6349 (0,604) | 10551 (0,751) | 15808 (0,803) |

| A5 MIT-‐4 | 9762 (0,390) | 15560 (0,632) | 21100 (0,737) |

| A5 MIT-‐5 | 12069 (0,246) | 18765 (0,557) | 24484 (0,695) |

(As already presented in the XXVI/9 report (UNEP, 2015)) Table 4-13 (and 4-14) shows the following (rounded) integrated total refrigerant demand for the three scenarios for the period 2020-2030 in Mt CO2-eq.:

BAU: 16,000 Mt CO2-eq.

MIT-3: 6,400 Mt CO2-eq.

MIT-4: 9,800 Mt CO2-eq.

MIT-5: 12,000 Mt CO2-eq.

The MIT-3 reduction from BAU of 9,500 Mt CO2-eq. represents a saving of 60%. In the case of the MIT-4 scenario, with a reduction of about 6200 Mt CO2-eq. compared to BAU, there is a saving of almost 40% from BAU. The MIT-5 reduction of 4,000 Mt CO2-eq. represents a smaller saving of 25% from BAU for this 2020-2030 period.

Values change calculated for the three scenarios in Mt CO2-eq. through 2050:

BAU: 80,200 Mt CO2-eq.

MIT-3: 15,800 Mt CO2-eq.

MIT-4: 21,000 Mt CO2-eq.

MIT-5: 24,500 Mt CO2-eq.

The MIT-3 reduction from BAU represents a saving of 80%. In the case of the MIT-4 scenario there is a saving of about 75% while the MIT-5 reduction of 56,000 Mt CO2-eq. compared to BAU represents a savings of 70% from BAU. There are still differences between the various MIT scenarios. However, the BAU demand for the entire period 2020-2050 becomes so large that the differences in reduction between the various mitigation scenarios MIT-3, -4 and -5 become less relevant.

A more reasonable estimate of the savings that can be realised via the various MIT scenarios may be the consideration of the period 2020-2040;

BAU: 42,300 Mt CO2-eq.

MIT-3: 10,600 Mt CO2-eq. 75% saving compared to BAU

MIT-4: 15,600 Mt CO2-eq. 63% saving compared to BAU

MIT-5: 18,800 Mt CO2-eq. 56% saving compared to BAU.

Another way to look at this is to analyse the trends in demand that are observed, as follows:

- Peak values determined for the refrigerant demand increase with a later start of conversion. The peak value for MIT-3 in 2020 is about 820 Mt CO2-eq. The peak value for MIT-4 in the year 2023, with conversion of stationary AC starting in 2025, is 25% higher (at 1025 Mt CO2-eq.), whereas the peak value for demand for MIT-5 in the year 2025 is 62% higher than the one for MIT-3 (at 1330 Mt CO2-eq.).

- For MIT-3, the average decline over a period of ten years after the peak year is 5.3% per year (from 820 down to 390 Mt CO2-eq. in 2030), for MIT-4 it is 4.5% per year (from 1025 down to 570 Mt CO2-eq. in 2033) and for MIT-5 it is 5.5% per year (from 1330 down to 605 Mt CO2-eq.). If the freeze year (which coincides with the peak year) is chosen as the starting point, an average annual reduction of 5% in total demand (manufacturing and servicing) seems feasible for all types of scenarios. These values all apply to a manufacturing conversion period of six years.

- For each separate Article 5 country the peak (freeze) values will still be in the same years for the various MIT scenarios considered, however, annual reduction percentages achievable thereafter may be significantly different per country.

4.7 References

| Campbell, 2015 | Campbell, N., Presentation at OORG meeting World Bank, “HFC Production and Demand”, May 2015 |

| Kaixian, 2015 | Kaixian, W., Presentation at OORG meeting World Bank, “HCFCs/HFCs Production in China”, May 2015 |

| Kuijpers, 2015 | Kuijpers, L., Private communications from chemical manufacturers, May-July 2015 |

| McCulloch, 2015 | Private communications with L. Kuijpers, May 2015 |

| Montzka, 2015 | S. A. Montzka, M. McFarland, S. O. Andersen, B. R. Miller, D. W. Fahey, B. D. Hall, L. Hu, C. Siso, and J. W. Elkins, Recent Trends in Global Emissions of Hydrochlorofluorocarbons and Hydrofluorocarbons: Reflecting on the 2007 Adjustments to the Montreal Protocol, J. Phys. Chem., dx.doi.org/10,1021/jp5097376, 2015 |

| Rigby et al., 2013 | M. Rigby, R.G. Prinn, S. O’Doherty, B.R. Miller, D. Ivy, J. Muehle, C.M . Hart, P.K. Salameh, T. Arnolds, R.F. Weiss, P.B. Krummel, L.P. Steele, P.J. Fraser, D. Young and .P. Simmonds, “Recent and future trends in synthetic greenhouse gas radiative forcing”, Geophysical Research Letters, 10,1002/2013GL059099 |

| RTOC, 2010 | UNEP, Refrigeration, AC and Heat Pumps Technical Options Committee, 2010 Assessment Report, ISBN 978-9966-20-002-0 |

| UNEP, 2015 | UNEP, Update Report of the XXVI/9 TEAP Task Force, September 2015, ISBN 978-9966-076-14-4 |

5 List of acronyms and abbreviations

| AHRI | Air Conditioning, Heating and Refrigeration Institute |

| AREP | Alternative Refrigerants Evaluation Program |

| ASHRAE | American Society of Heating, Refrigerating and Air Conditioning Engineers |

| ASTM | American Society for Testing and Materials |

| CEN | European Committee for Standardisation |

| CFC | Chlorofluorocarbon |

| CO2 | Carbon Dioxide |

| COP | Coefficient of Performance |

| EPA | US Environmental Protection Agency |

| EU | European Union |

| GWP | Global Warming Potential |

| HC | Hydrocarbon |

| HCC | Hydrochlorocarbon |

| HCFC | Hydrochlorofluorocarbon |

| HCFO | Hydrochlorofluoroolefin |

| HCO | Oxygenated hydrocarbon |

| HFC | Hydrofluorocarbon |

| HFO | Hydrofluoroolefin |

| HTOC | Halons Technical Options Committee |

| IIR | International Institute for Refrigeration |

| IPCC | Intergovernmental Panel on Climate Change |

| ISO | International Organisation for Standardisation |

| LCA | Life Cycle Analysis |

| LCCP | Life Cycle Climate Performance |

| MBH | Thousand BTUs per Hour |

| ODP | Ozone Depletion Potential |

| ODS | Ozone Depleting Substance |

| OEL | Occupational Exposure Limit |

| R/AC | Refrigeration and Air Conditioning (also RAC&HP) |

| RTOC | Refrigeration, AC and Heat Pumps Technical Options Committee |

| SNAP | Significant New Alternatives Policy |

| TEAP | Technology and Economic Assessment Panel |

| TEWI | Total Equivalent Warming Impact |

| TLV | Threshold Limit Value |

| UL | Underwriters Laboratories Inc. |

| UNEP | United Nations Environment Programme |

| VOC | Volatile Organic Compound |

.png)

.jpg)